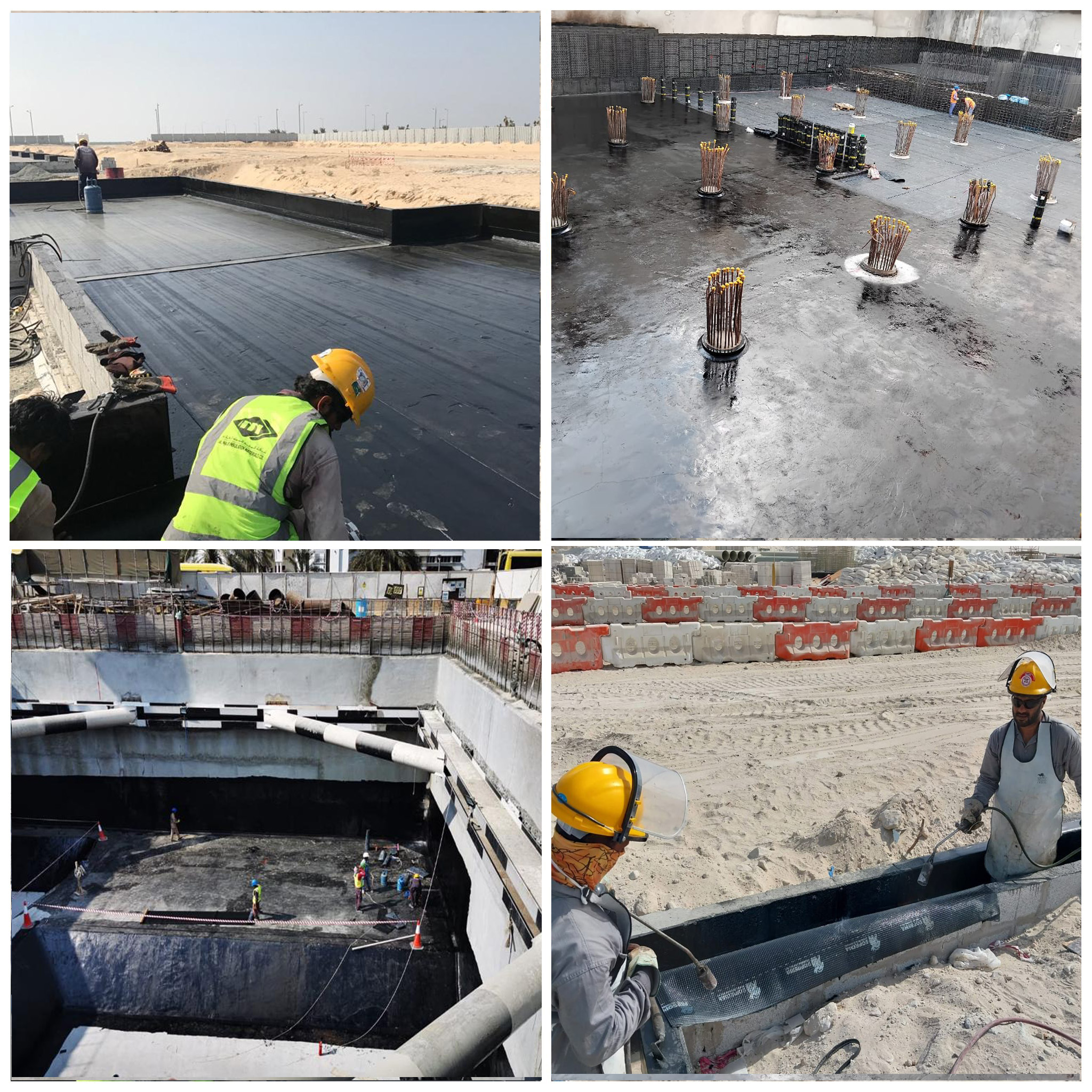

Substructure Area Waterproofing

Substructure Waterproofing is the method of forming a barrier over surfaces of foundations, walls and other structural members of buildings to prevent the passage of water under hydrostatic pressure. Usually utilized materials for below grade waterproofing are Torch applied membrane with protection, Bituminous coating, Polyurethane coating etc.

The bituminous waterproofing membranes are used to waterproof underground structure. It comes in rolls of different lengths and thicknesses. As the rolls are installed using blowtorches, one must use fire precautions and all safety measures against fire burns.

Oxidized Bitumen is a solid or semi-black solid material and gradually liquid when heated. Oxidized Bitumen grades are blown or oxidized Asphalt ‘s which are produced by passing air through soft bitumen under controlled temperature conditions.

It is used as raw material for bitumen coat, insulation and isolation bitumen membrane sheet, road construction, sealing and insulating buildings, etc.

The pile head is the point where the pile is connected to the structure. For concrete floor slabs, pile heads are very important additions to piles as they help to reduce the maximum bending moment experienced by the slab, by reducing the effective span. They also reduce the chance of the slab failing by punching shear from the pile. Pile caps connect groups of piles to distribute loads over the capped piles.

Pilehead treatment system comprises of three step application, whereby the pile head is repaired, waterproofed and protected from chloride and sulfate attacks on the reinforcement and the passage of water from the ground to the substructure. Following are the steps,

1. Reprofiling: Micro concrete or Cementitious grout is used to reprofile the pile head to make an even surface to received waterproofing. Also, it prevents the underground water to seepage by capillary force along the reinforcement bars into the pile cap.

2. Dressing: Where the reprofiled pile is make watertight by applying suitable means of waterproofing system.

3. Encapsulation: The Pile head is then encapsulated with epoxy grout to ensure complete water tightness.

Basement waterproofing is required when a structure or property, or part of a property, is built below ground level. It is likely that there will be a build-up of water in the ground surrounding the basement, raising the water table, leading to hydrostatic water pressure. This water pressure is exerted on the floor and walls of the basement and can lead to water penetration through cracks, joints and structural weaknesses in the basement.

When a leakage is found, a quick and effective repair is needed to minimize further damage from water ingress. Our team is at hand to efficiently perform all manner of leakage repairs, with the majority of work being performed externally for minimal disturbance.

Concrete Crack Injection is the preferred repair method for both cracks in horizontal concrete foundations and vertical concrete surfaces. It also is used to eliminate moisture intrusion in cracks left from other foundation repairs.

Concrete expansion joints must be sealed with a flexible sealant or an expansion joint strip, to prevent water from penetrating the joint and deteriorating the sub base.

High performance, crack-bridging and fully controlled. Highly flexible waterproofing systems using water stopper based sheet waterproofing membranes are installed externally and cover the entire basement structure in contact with the ground. The waterproofing layer is divided into ‘compartments’ with a network of cast in place compatible waterstops that are welded to the membrane.

- Water-stopper

- Swellable bar

- Injection hose